Sande Settefisk signs contract new RAS facility with Sterner

- 5. april 2021

Sande Settefisk in Gloppen, Norway, is establishing a new plant for the production of post-smolt, and Sterner is constructing the plant.

The new production unit will increase the annual capacity from 1 to 5 million smolts. The facility will produce salmon and rainbow trout, and will supply Nordfjord Laks and Svanøy Havbruk, fish farms who in addition to Hyen Fisk are the owners of Sande Settefisk.

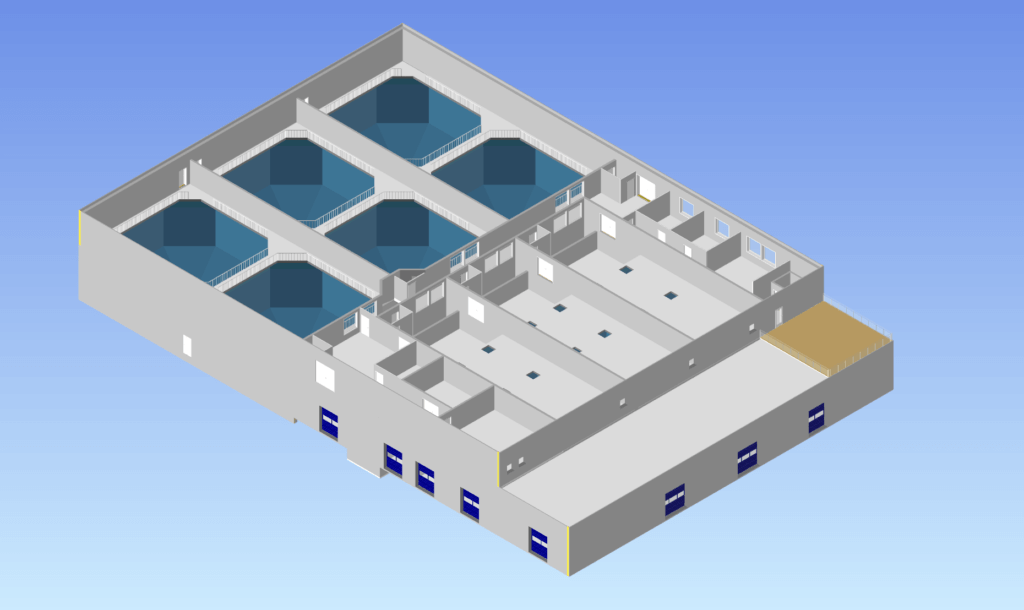

The plant will be built by Sterner and will consist of 3 departments, each with a maximum feed of 1500 kg.per day, a total of 4500 kg.

«It was undoubtedly Sterner’s technology that made us choose them to build this facility. Sterner has more than 30 years of experience in technology for clean water, very good references and components that are the leaders in the market. Good water quality gives good economy. » Tells Svein Klævold, chairman of the board of Sande Settefisk, and adds: «In addition, Sterner has been unique in professionalism throughout the tender process.»

The new facility will consist of a total of three separate main departments:

- Hatchery with start feeding line based on RAS technology

- Ongrowth 1, which is a flow-through facility

- Ongrowth 2, based on RAS technology.

With this expansion, the total tank capacity of the entire plant will be a total of 8000 cubic meters.

The total investment for the completed hatchery and ongrowing facility will be close to 250 MNOK

Sterner will also deliver sludge treatment to the entire plant, with its MAT technology which ensures that the sludge can be distributed further for fertiliser in Norwegian agriculture.

«We are very proud of this,» says Tom Wilke, general manager at Sande Settefisk. «Through the negotiation process with Sterner, it has been important for us to facilitate the use of local providers / contractors. The investment will also provide more new jobs to the municipality ».

«We are very grateful for the trust, and look forward to starting this project in collaboration with Sande Settefisk. This is a plant that will be incredibly cost-effective, and we expect particularly good results in production based on previous experience with similar designs on plants. » Mr. Pettersen tells.